What We Offer

Cristex offers a range of Hybrid Woven and multi-layer fabrics with weave patterns such as plain, twill or satin. The most common Hybrid combinations will typically be,

Carbon / Aramid – The high impact resistance and tensile strength of the Aramid Fibre combined with a high compressive and tensile strength of Carbon. Both fibres have low density but relatively high cost.

Glass / Aramid – The low density, high impact resistance and tensile strength of Aramid Fibre combined with the good compressive and tensile strength of Glass, coupled with its lower cost.

Carbon / Glass – Carbon Fibre contributes high tensile compressive strength and stiffness and reduces the density, while Glass reduces the cost.

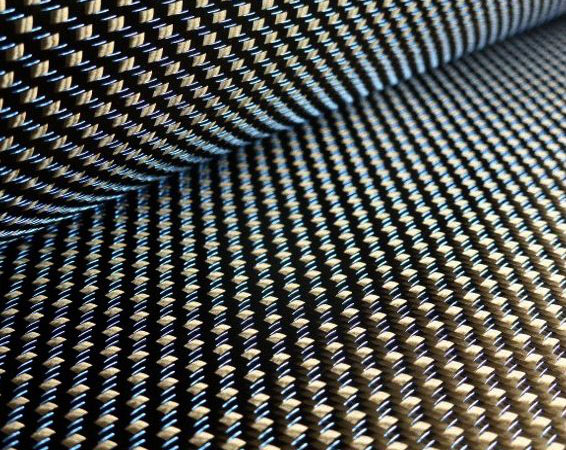

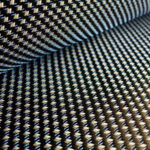

Carbon, Aramid and Diolen Hybrid Fabrics

| Datasheet | Reference | Weight g/m2) | Weaving Style | Warp | Weft | Ends cm | Warp | Weft | Width cm |

|---|---|---|---|---|---|---|---|---|---|

| GK 165 P | GK 165 P | 165 | Plain | 36% Carbon 15% Aramid | 18% Carbon 31% Aramid | 5.0 | Carbon 3K + Aramid 1610 | Carbon 3K + Aramid 1610 | 100 |

| GK 170 P | GK 170 P | 165 | Plain | 65% HM Polyester 35% Aramid | 33% HM Polyester 67% Aramid | Warp: 3.3 + 1.7 Weft: 1.7 + 3.3 | Black HM Polyester 167 tex + HM Aramid 1610 dtex | Black HM Polyester 167 tex + HM Aramid 1610 dtex | 120 |

| GK 210 T | GK 210 T | 210 | 2/2 Twill | 61% Carbon 39% Aramid | 61% Carbon 39% Aramid | 6.4 | Carbon 3K + Aramid 1210 | Carbon 3K + Aramid 1210 | 120 |

Glass and Aramid Hybrid Fabrics

| Datasheet | Reference | Weight g/m2 | Weaving Style | Warp | Weft | Ends cm | Warp | Weft | Width cm |

|---|---|---|---|---|---|---|---|---|---|

| VK-390 T | VK 390 T | 396 | 2/2 Twill | 35% E-Glass 15% Aramid | 35% E-Glass 15% Aramid | 4.8 | E-Glass 600 TEX + Aramid 2420 | E-Glass 600 TEX + Aramid 2420 | 127 |

| VK 390 T + Mat 225 | VK 390 T + Mat 225 | 621 | 2/2 Twill | 70% E-Glass 30% Aramid | 70% E-Glass 30% Aramid | 4.8 | E-Glass 600 TEX + Aramid 2420 | E-Glass 600 TEX + Aramid 2420 | 127 |

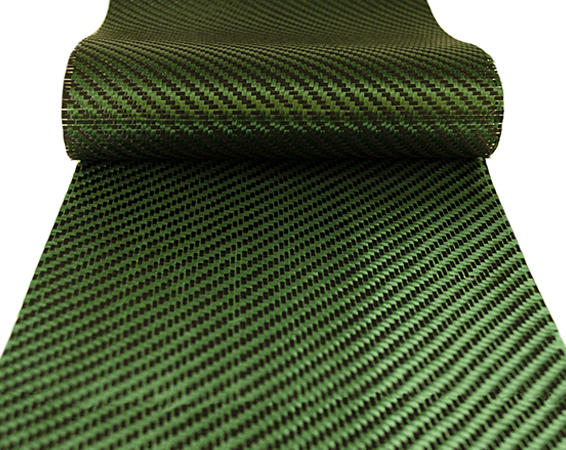

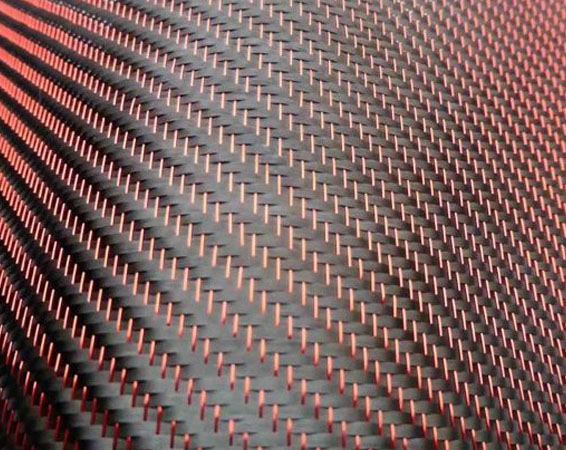

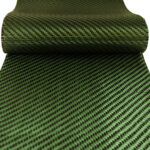

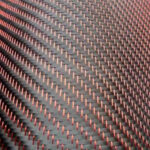

Carbon and Coloured Polyester Fabrics

| Datasheet | Reference | Weight g/m2 | Weaving Style | Warp | Weft | Wrap | Weft | Width cm |

|---|---|---|---|---|---|---|---|---|

| GDc 210 P Blue | *GDc 210 P Blue | 206 | Plain | 47% | 53% | 3K Carbon Fibre 200tex | Blue Polyester 1000 dtex | 100 |

| GDc 210 T Blue | GDc 210 T Blue | 206 | 2/2 Twill | 47% | 53% | 3K Carbon Fibre 200tex | Blue Polyester 1100 dtex | 100 |

| GDc 210 P Green | * GDc 210 P Green | 206 | Plain | 47% | 53% | 3K Carbon Fibre 200tex | Green Polyester 1100 dtex | 100 |

| GDc 210 T Green | GDc 210 T Green | 206 | 2/2 Twill | 47% | 53% | 3K Carbon Fibre 200tex | Green Polyester 1100 dtex | 100 |

| GDc 210 P Red | * GDc 210 P Red | 206 | Plain | 47% | 53% | 3K Carbon Fibre 200tex | Red Polyester 1100 dtex | 100 |

| GDc 210 T Red | GDc 210 T Red | 206 | 2/2 Twill | 47% | 53% | 3K Carbon Fibre 200tex | Red Polyester 1100 dtex | 100 |

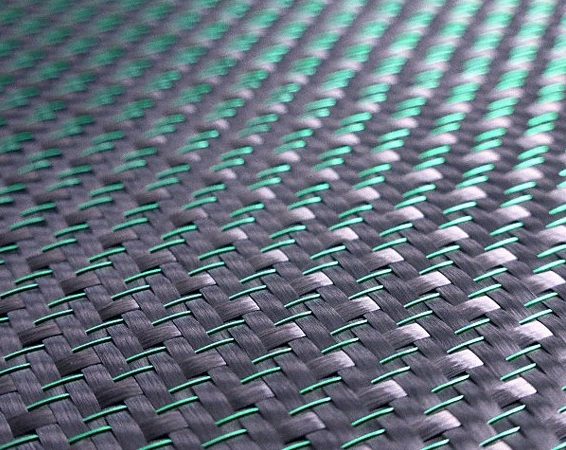

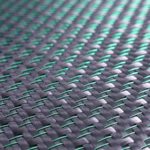

Coloured Copper Wire (Innovative tex)

| Datasheet | Reference | Weight g/m2 | Weaving Style | Warp | Weft | Width cm |

|---|---|---|---|---|---|---|

| GGCu 300 T Red | GGCu 300 T Red | 300 | 2/2 Twill | 3k Carbon 200 tex | Red Copper wire + 3K Carbon | 100 |

| GGCu 300 T Blue | GGCu 300 T Blue | 300 | 2/2 Twill | 3K Carbon 200 tex | Blue Copper wire + 3K Carbon | 100 |

| GGCu 300 T Green | GGCu 300 T Green | 300 | 2/2 Twill | 3K Carbon 200 tex | Green Copper wire + 3K Carbon | 100 |