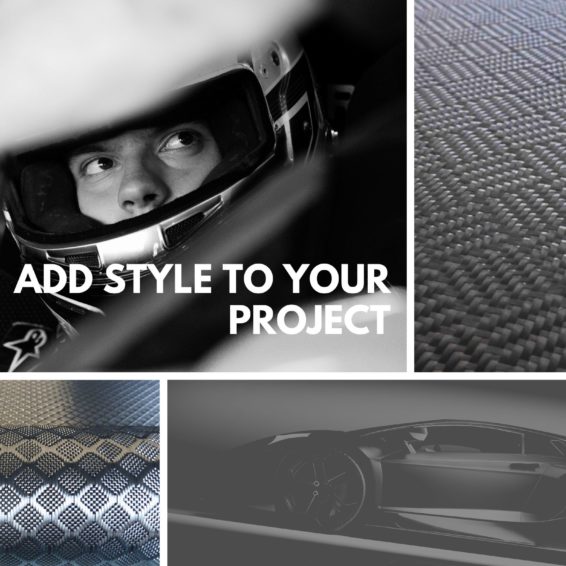

What We Offer

Cristex offers the ultimate range of Decorative Fabrics for composite applications. See the available ranges below.

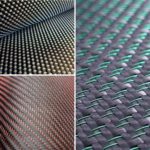

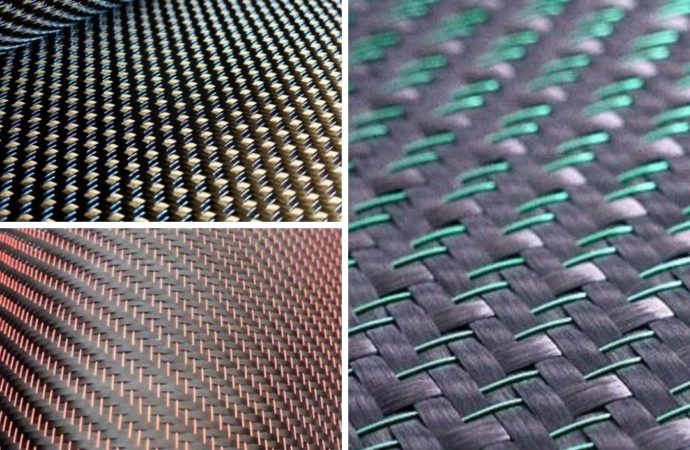

Premium Decorative Weaves

The Premium Weave collection is a new addition to the decorative fabric range.

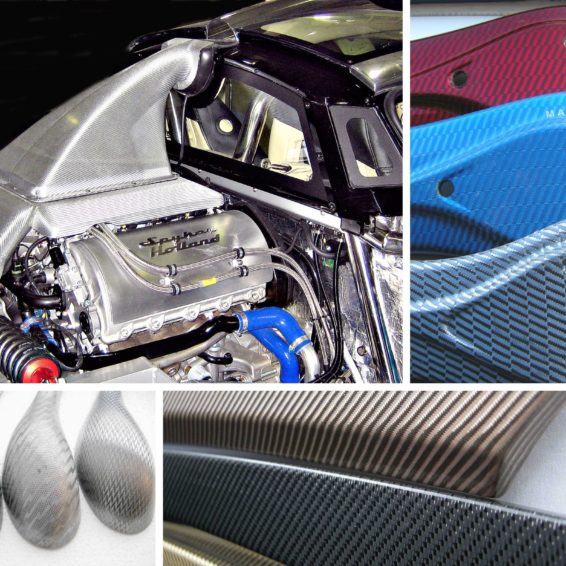

Alutex

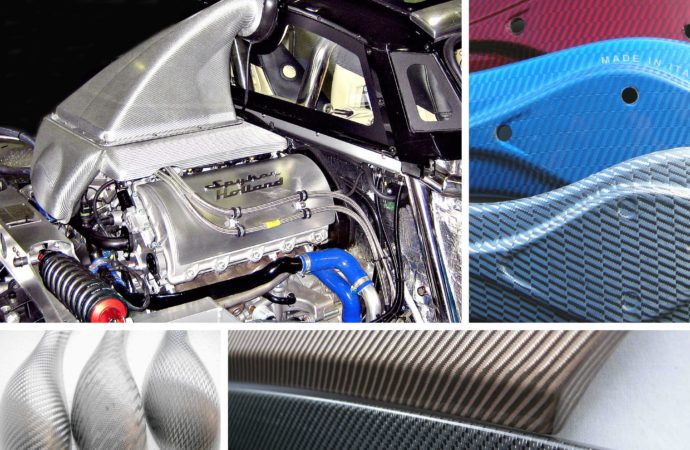

Alutex is a range of Woven Glass fabrics typically 200g to 300g of varied weave patterns. These fabrics are powder coated using an aluminium powder to create the finished look.

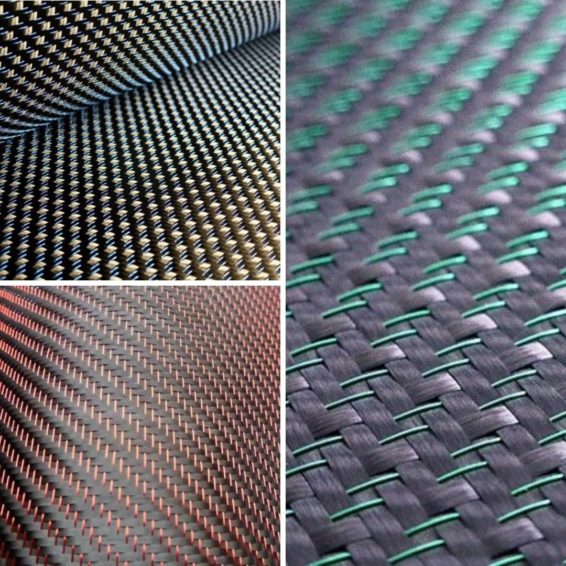

Innovative Tex

Originally designed with Aerospace applications in mind, the combination of Carbon with Copper was successfully tested for lightning strike on the leading edge. More recently the combination of Carbon with Metallic Threads has been widely embraced by the Automotive Industry as an effective alternative to standard Carbon Woven fabrics, for internal decoration.

The Innovative range has been extended with the development of coloured metallic threads, providing the end user with an alternative to traditional coloured Carbon fabrics. The development of coloured Metallic Threads creates fabrics with vibrant colours even after laminating. Unlike traditional dyed yarns (typically Polyester or Polypropelene) the use of colour in the Metallic Threads does not lose any brilliance after lamination.

The Innovative range includes standard style weaves such as plain and twill, but also many designs, unique to this family of fabrics.

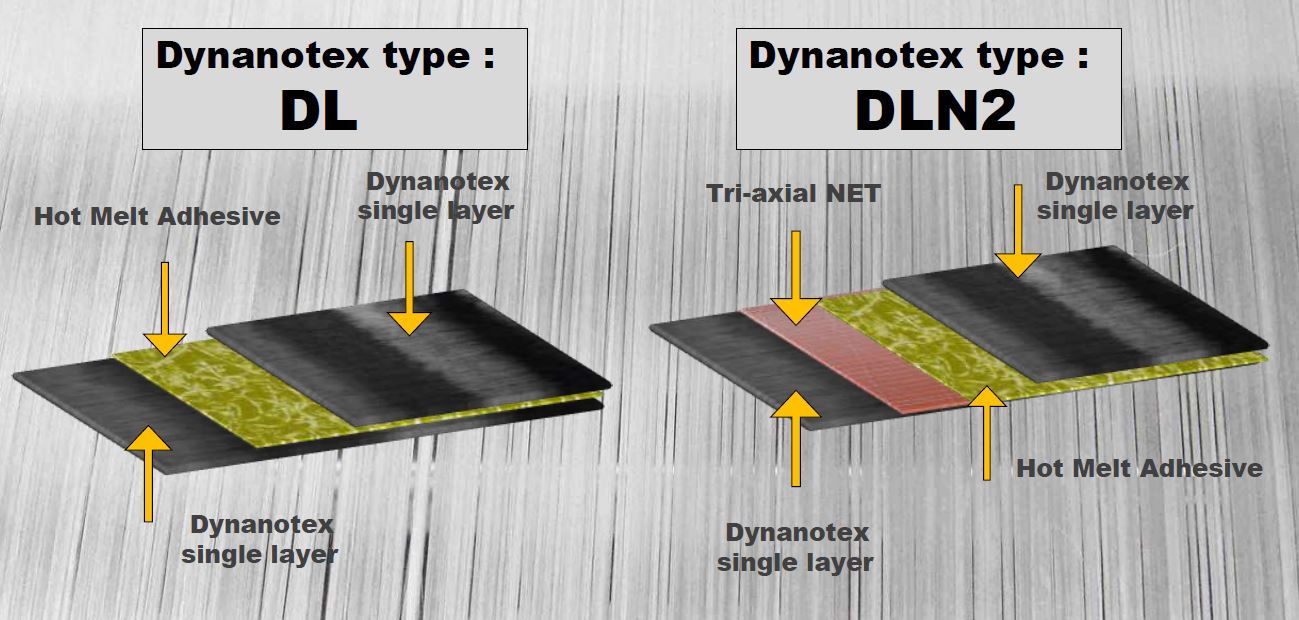

Dynanotex

Dynanotex is a Tow Spreading System for the production of Unidirectional Carbon Fibre reinforcements. The Dynanotex concept is based on two separate layers of Unidirectional Carbon Fibre bonded together by Resin compatible adhesive. Essentially a Tow Spreading System creating a Unidirectional sheet of Carbon Fibre which can then subsequently be cut to varying widths and used in the production of woven Dynanotex. Dynanotex fabrics both UD and woven have:

- No additional surface treatments

- Perfect fibre alignment

- Thickness reduction (35% less than traditional UD reinforcements)

- Low weight reinforcements (70 to 200g/m²) from heavy tow fibres (15K-24K-50K)

- Perfect alignment of fibre maximises the mechanical performance of the fibres

- Improvement of interlaminar sheer strength as a result of the perfect bonding of fibres layers

- Reduction/Elimination of resin build up due to the excellent fibre distribution

Dynanotex fabrics are used in wind surfing, kite boarding, skis, hockey sticks and sports goods in general, automotive and marine applications.

UD Glass Dynanotex

A recent development in the Dynanotex family has been the creation of UD Glass Fabrics. Based on heavy roving typically 1200 TEX a range of UD Glass Fabrics has been created with weights from 150g to 305g.